A few nights ago, I woke up in the middle of the night with a terrible feeling that I couldn't breathe. Very soon I realized I had a terribly stuffy, itchy nose, and a sore throat. I've been suffering from these symptoms for a few days now. While everyone in my household has taken a turn at a viral fever over the last few weeks, I know for a fact that I am suffering from seasonal allergies, not a viral infection. It's that time of year again, when environmental airborne allergens are high. Having lived in Austin for 15 years now, I am very familiar with seasonal allergies, especially sniffles caused by hay fever and cedar fever. I myself developed nasal allergies just a few years ago. For me, it usually starts in late December/ early January, when juniper (mountain cedar) pollen is at it's highest, and continues through late spring, when oak pollen abounds, and everything in the city is covered in yellow dust.

Most people start out experiencing allergies in one season, that then expands to two seasons, and soon they have year round allergies. All too common in Austin.

So, if you call Austin home, and you are allergy-free, count your blessings! Also, make the most of it, because, rumor has it - there is a high probability that you will be under an allergy attack in a few short years. And then, brace yourself!

Along with my nasal steroids and anti-histamines, I arm myself with an app on my phone that alerts me on the allergen of the day and it's count.

This time, the culprit is mold. Mold is a perennial allergen that thrives in moist conditions that are prevalent outdoors after rainfall or indoors in wet areas. Mold sporulates in the darkest hour of the night (which explains why I woke up feeling suffocated at 2am), as opposed to pollen which is highest in the wee hours of the morning.

Is your indoor air cleaner than outdoor air?

When outdoor allergens are in the red zone, the common recommendation is to stay indoors. But the truth is, you are not as protected indoors as you would think. Do you know the quality of your indoor-air?

There is plenty of air-exchange between the inside and outside of a house, even when your doors and windows are closed. The older the house, the higher the chances are that the inside is not sealed from the outside. Even houses that are built today are not as airtight as they could be. There are gaping holes in the walls, ceilings, and roofs. Vents, lights, plumbing and electrical penetrations, gaps around windows and doors, fireplace chimneys, connections between different materials, etc., all puncture the inside-outside barrier and unintentionally let the outside in.

Moreover, the mechanical system is (intentionally) mandated to bring "fresh air" from outside into the house to meet ventilation requirements. This air is seldom treated or controlled.

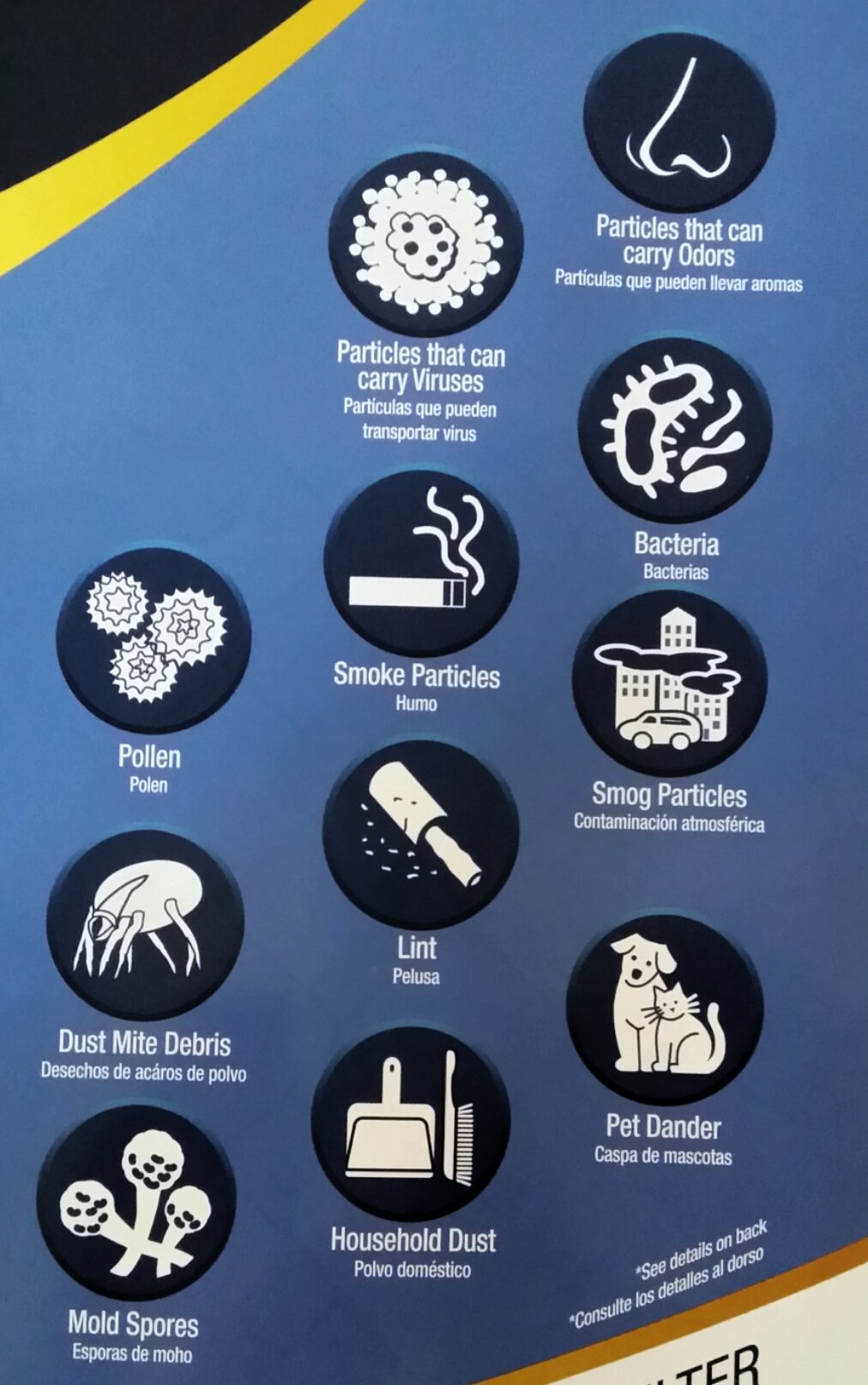

Then, there are the allergens generated inside the building - dander, dust, mold, etc. All this affects the quality of your indoor air. There are visible and invisible particulate matter suspended in the air you breathe. There are also chemical contaminants, which is another topic.

The role of the air-conditioner

Your air-conditioner is supposed to "condition" the air that it circulates through the house. “Condition” meaning to clean and disinfect, in addition to cool and dehumidify. But most air-conditioner units, specifically mechanical systems installations, are designed to do one thing most effectively, and that is, cool the air! The rest is done inadequately.

For effective results, it's a good idea to take care of each task of air-conditioning separately. So, if you are replacing your indoor air-handler unit, you have an opportunity to upgrade your system.

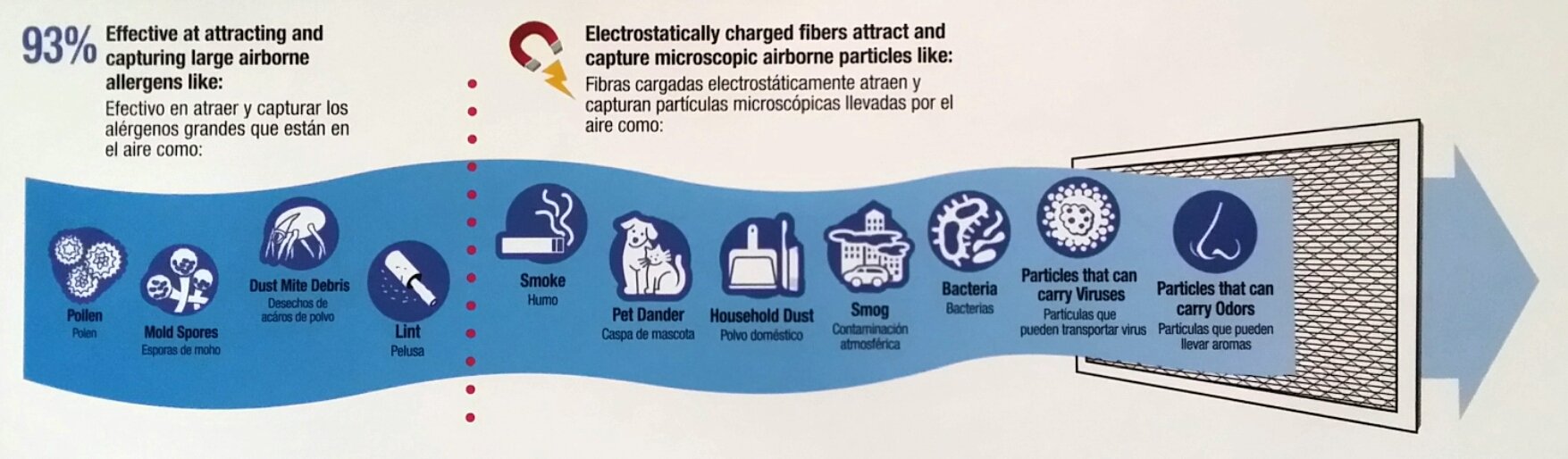

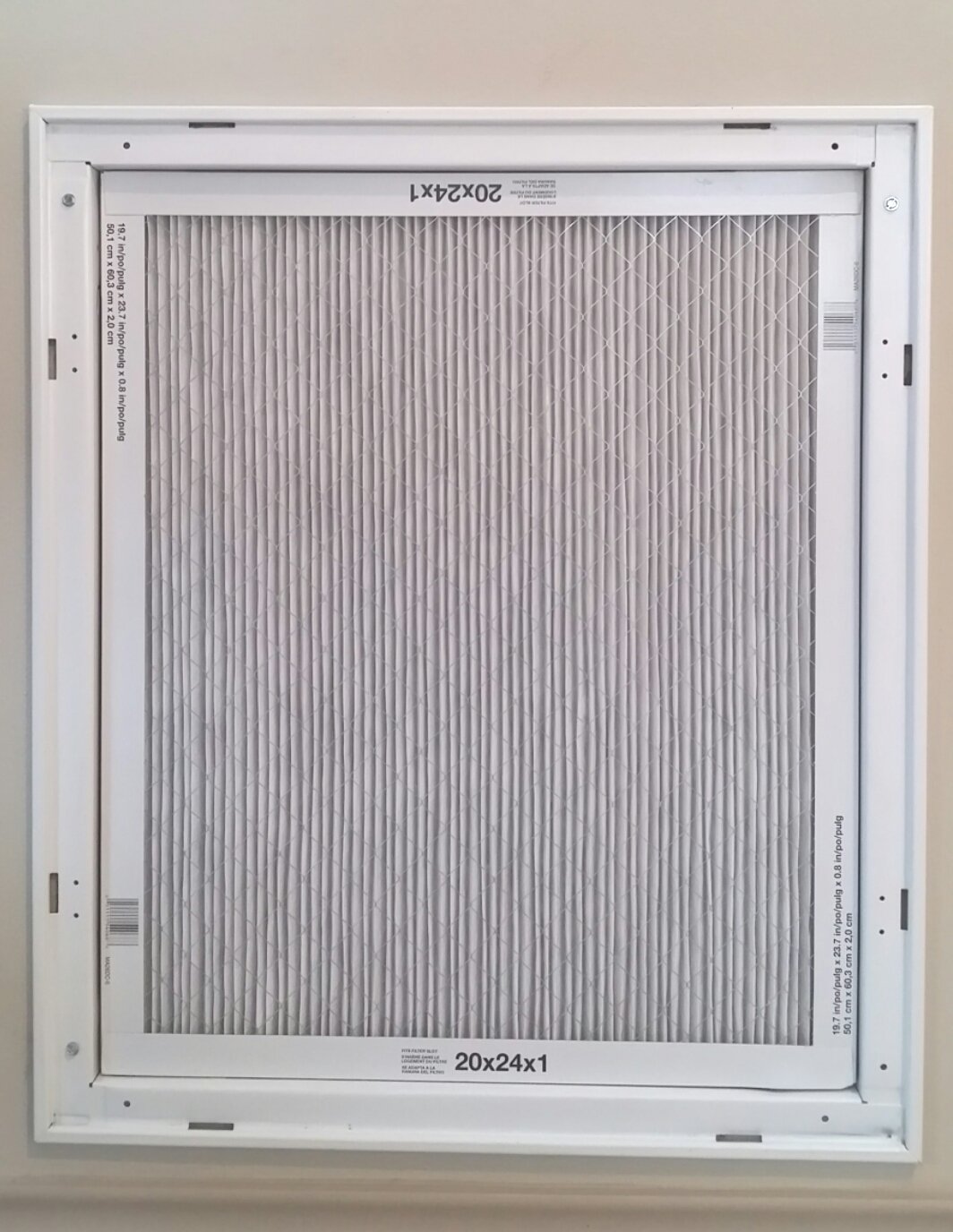

The best way to make sure that air recirculated by your air-conditioner is clean, is to get the best filter you can afford. Most homes in America have a 1” thick filter behind a return air grille located in the wall or ceiling. It’s better to have a thick pleated (accordion) air filter with a High MERV (Minimum Efficiency Reporting Value) rating (ranges from 1 through 16). These are typically located at the air handler unit (AHU).

The last time I upgraded my ac system, I got a 7" thick pleated MERV 10 filter, located at the air handler unit, in addition to the filter at the return air grill on the wall.

The filter is the first (and sometimes only) line of defense. It blocks particulate matter before it enters the air handler unit, thereby limiting the debris on the evaporator coil and blower inside the unit. Dirty coils and blower leads to efficiency loss and also contamination of condensate pan below, which then leads to clogged drain lines. Imagine a dirty, moldy broth at the bottom of your unit (inside).

There are other techniques and products available to purify and disinfect air. Selection depends on target - UV lamps, adsorption, Ionizers, Ozone generators, etc.

Maintenance of AC filters

My allergy attack reminded me to replace my AC filters. And it was as yucky as you can imagine. Unfortunately, I only have the protection of a regular 1" thick household filter at the return air grill in the wall. I sorely miss the 7" thick pleated filter at my old house. I would have liked to clean out the condensate pan, but the drain line coming out of my AC unit was not set up to allow that (i.e no clean out, T-fittings, or valves).

When was the last time you did any house keeping or maintenance on one of the most important systems in your house - the one that is controlling the air you breathe? (This is not a guilt trip. I am just as guilty.)

If you haven't already done so:

change the air filter at each return air grill in the wall or ceiling, every 3 months

if you have a thick pleated air filter at the unit, replace that once a year

if you have a UV light in your return air chase or inside the unit, change it out every 2 years

clean out condensate pan and drain line, once a year with bleach water (if you have the right set-up)

set up an annual a/c maintenance and they can take care of all of the above along with other stuff

Are you building new?

If you are building a new house right now, take a step back and discuss your indoor air quality, especially if you suffer from environmental allergies. How are you preventing outdoor air pollutants from entering your house? And what are you doing to mitigate indoor air pollutants?

You may not have allergies, or asthma, or any related health issues now, but what about the future? What about your kids?

Your health and comfort are at stake. It pays to take a comprehensive approach to the design and construction of the entire house, in addition to thoughtful design and installation of mechanical systems.

Cheers,

Sharon